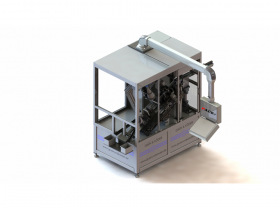

PACE V is an inspection machine for headless parts, axis’s, turned parts, pins, etc.

A massive steel frame makes the machine extremely robust and stable.

The feeding unit usually equipped with a vibrating bowl is in a separate housing to avoid vibrations influencing the inspection process.

A linear acceleration conveyor transports the parts into the inclined V chute.

The inspection area for the camera is not as usual a glass chute.

We are using our PACE-VR-Chute, a special chute operating without glass, made for an extremely exact and precise positioning of the part. There are no distortions through glass, no pollution with dirt or other influences. The camera takes its shot “through air”.