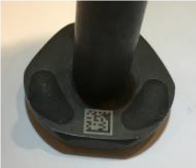

Marking all good parts with a printed number, bar code or text, with an ink printer. With this system you can archive a complete trackability.

Also used to read information’s about the parts, or to testify that it had been inspected.

As well it is used with invisible ink to proof to your customer that this part was undergoing a 100% inspection process, in case of unclear arguments.

To have a permanent check of the machine reliability in the sorting process, master pieces can be fed automatically to the machine. Recognized by a DMC code on the part the master piece and its test plan the machine will check all relevant test parameters automatically and gives a report/warning if something is not correct.

This process allows a fully documented reliability report over a full shift or longer.

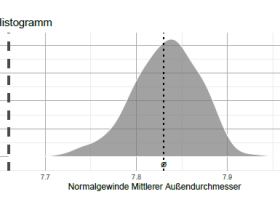

Optional the PACE can be equipped with a separate data server. All data of the inspection process can be stored, analysis and printed into scales and statistic protocols. Any task, any structure of data analysis is possible

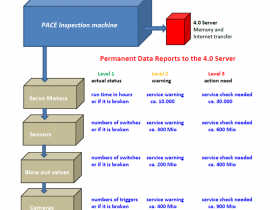

From July 2018 the PACE can be equipped with Industry 4.0 modules.

All machine parts and unit’s activities can be watched, protocolled, and reported.

Internet connections with remote process watching is also possible the modules are modular and can be selected as necessary.