Optical

Optical detection of cracks with the head camera or the THETA 3D camera. All visible cracks can be detected and analyzed. With the head camera a speed up to 1.500 parts / minute is possible.

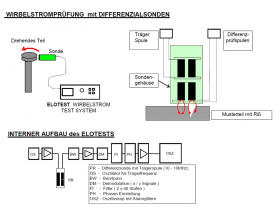

Eddy current

Dynamical differential system with eddy current probes.

A process to find visible and INVISIBELE cracks inside the material. The parts are rotating and tested with the probe at its circumference. The rotation is been controlled with an accuracy of 0,3 degree.

Positions of the test probe

- Head circumference

- Under the head

- Shank

- Thread

- On the head

- At multi positions around a ball head

Polygon inspection / not round heads

For the inspection of not round heads, hexagon heads or any polygon curved part the probe can either been regulated with our electronical distance compensation, or it can be moved with our EDC-system for distance differences up to 15 mm.