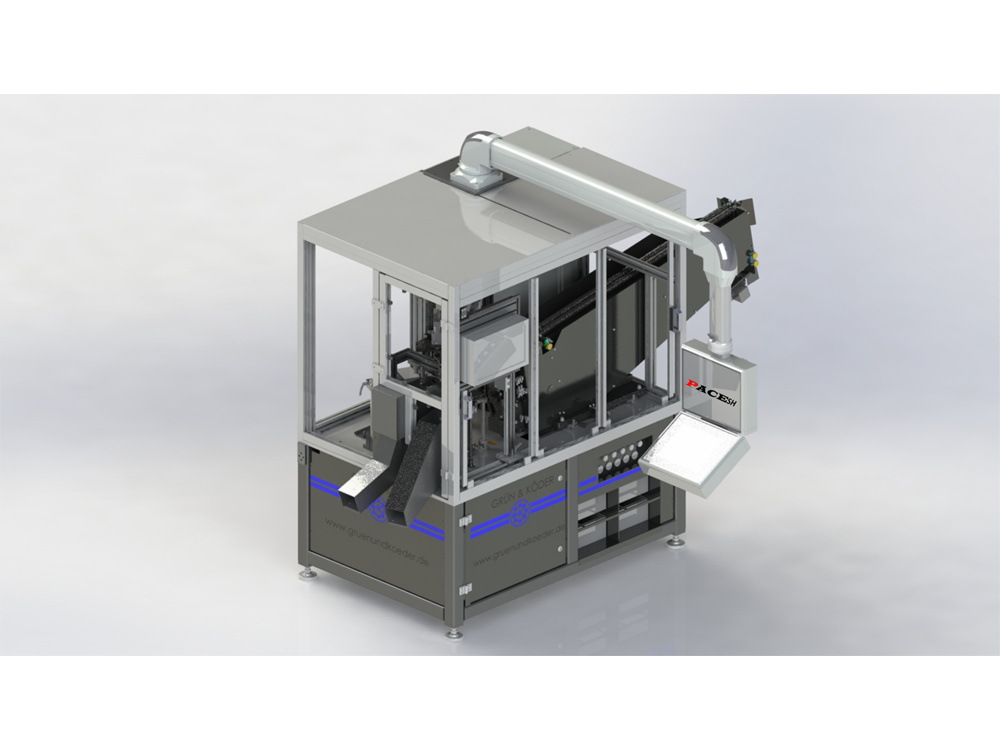

PACE SH is a machine using a rotating steel disc where the parts are moved in a hanging position. Mainly screws, bolts, rivets, etc.

A massive steel frame makes the machine extremely robust and stable.

The feeding unit usually equipped with a vibrating bowl is in a separate housing to avoid vibrations influencing the inspection process.

We can offer different feeding solutions, for example vibrating bowls, step feeder, special bowl for head heavy parts, etc.

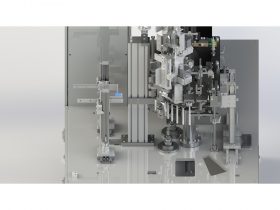

The parts are fed over rotating rollers and rails into the disc. On the rollers the parts getting orientated and pre-selected through their head diameter.

The disc (up to 300 mm diameter) can be equipped with 12 – 60 slots to archive the optimum speed related to the parts geometry.

The disc is very easy to change over.

Speed up to 1.500 parts / minute